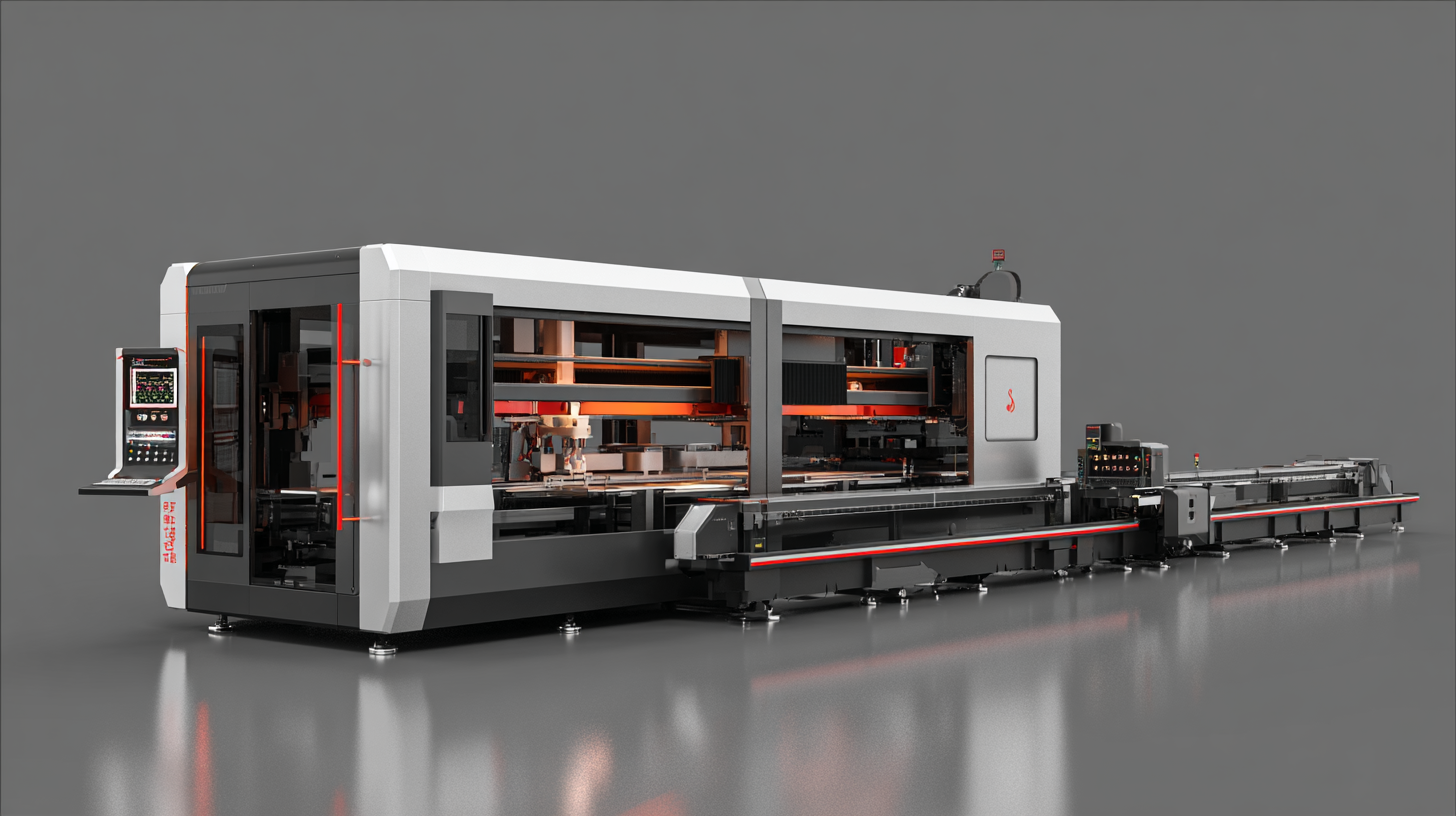

Unlocking the Future of Manufacturing with Best Rtms Machine and Strategic Innovations for 2025

The rapidly evolving landscape of manufacturing is being significantly shaped by strategic innovations, particularly the advancement of Rtms Machines. According to a recent report by McKinsey & Company, the adoption of advanced manufacturing technologies could increase productivity by up to 30% by 2025. This surge in efficiency is critical as companies across various sectors seek to enhance production capabilities while minimizing costs. The diverse characteristics and applications of different products necessitate tailored approaches in manufacturing processes, making the integration of Rtms Machines an essential consideration. Notably, a study from Deloitte highlights that 70% of manufacturing executives believe advanced technologies, like Rtms Machines, will be crucial in defining competitive advantage in the coming years. Therefore, unlocking the full potential of these machines not only positions businesses for immediate efficiency gains but also paves the way for sustainable growth in an increasingly competitive market.

Identifying the Key Traits of Quality Suppliers for Advanced Manufacturing

In the rapidly evolving landscape of advanced manufacturing, identifying key traits of quality suppliers is crucial for success. First and foremost, suppliers must demonstrate a commitment to innovation. Companies should seek partners that invest in cutting-edge technologies and research to enhance production processes and product quality. An innovative supplier can adapt to market changes and provide solutions that give their customers a competitive edge.

Another essential trait is reliability. A quality supplier must have a proven track record of consistent performance and timely delivery. This reliability ensures that manufacturing schedules remain uninterrupted and that the final products meet market demand. Additionally, strong communication skills are vital, enabling suppliers to collaborate effectively with manufacturers to address any challenges that may arise promptly.

Lastly, a focus on sustainability is increasingly important in the supplier selection process. As industries strive to minimize their environmental impact, suppliers that prioritize sustainable practices can help manufacturers achieve their ecological goals. By aligning with suppliers who share similar values regarding sustainability, manufacturers can foster a supply chain that not only supports innovation and quality but also promotes responsible production methods.

Unlocking the Future of Manufacturing: Key Traits of Quality Suppliers for Advanced Manufacturing in 2025

This chart illustrates the critical traits that manufacturers value in their suppliers as we look towards 2025, highlighting the importance of innovation, reliability, and sustainability.

Leveraging Technology to Enhance Supplier Evaluation Processes

In an era where technology continues to reshape every sector, the need for effective supplier evaluation processes has never been more critical for manufacturers. Leveraging advanced technologies such as artificial intelligence (AI) and data analytics can significantly enhance how companies assess their suppliers. By utilizing machine learning algorithms, organizations can analyze vast amounts of data to identify patterns and trends, enabling more informed decision-making. This technological integration allows for a more dynamic evaluation framework, moving beyond traditional metrics to encompass real-time performance insights and predictive capabilities.

Moreover, incorporating an innovative approach to supplier evaluation not only streamlines procurement but also fosters stronger relationships between manufacturers and their suppliers. With tools that provide transparency and facilitate communication, businesses can create a collaborative ecosystem that encourages improvement and accountability. As manufacturing companies gear up for 2025, adopting these strategic innovations will lead to a more resilient supply chain, enabling them to respond swiftly to market changes and demands. The future of manufacturing lies in the ability to adapt, and by embracing technology to enhance supplier evaluation processes, companies can unlock significant competitive advantages.

Unlocking the Future of Manufacturing with Best RTMS Machine and Strategic Innovations for 2025

| Innovation Area | Description | Expected Outcome | Implementation Timeline |

|---|---|---|---|

| AI-Driven Supply Chain | Utilizing artificial intelligence to optimize inventory management and forecast demand. | Improved accuracy in supply forecasting and reduced stock-outs. | Q1 2025 |

| IoT Integration | Implementing Internet of Things (IoT) for real-time tracking of production processes. | Enhanced visibility and control over manufacturing operations. | Q2 2025 |

| Blockchain for Supplier Transparency | Leveraging blockchain technology to improve traceability in the supply chain. | Increased trust and reduced fraud among suppliers. | Q3 2025 |

| Advanced Analytics | Utilizing big data analytics to improve supplier performance evaluations. | Data-driven decisions leading to better supplier selection. | Q4 2025 |

Strategies for Building Long-Term Partnerships with Quality Suppliers

Building long-term partnerships with quality suppliers is crucial for unlocking the potential of manufacturing in 2025. By focusing on collaboration and mutual growth, companies can ensure a more resilient supply chain and enhance their product offerings. Effective communication is the key to establishing trust and understanding between manufacturers and suppliers. Regular meetings and transparent dialogues can foster a strong relationship that withstands market fluctuations.

Tip: Evaluate potential suppliers not just on price, but also on their reliability, quality standards, and innovation capabilities. A supplier that invests in their technology and processes can lead to improved outcomes for your own operations.

Additionally, investing in joint training sessions and development programs can strengthen these partnerships. By sharing knowledge and resources, both manufacturers and suppliers can stay ahead of industry trends and challenges. This commitment to continuous improvement will not only enhance product quality but also drive innovative solutions that benefit both parties.

Tip: Create a partnership framework that encourages feedback and regular assessments of performance metrics. This proactive approach allows for the identification of areas for improvement and helps in setting shared goals, making your partnership more productive and aligned with future manufacturing trends.

Navigating the Global Market: Finding Reliable Suppliers Beyond Borders

In today’s increasingly interconnected world, manufacturing companies are navigating a complex global market that requires them to look beyond their borders for reliable suppliers. According to a report by McKinsey & Company, 30% of manufacturers are diversifying their supplier base to mitigate risks and enhance resilience. Establishing partnerships with international suppliers not only helps to secure supply chains but also opens new avenues for innovation and efficiency. For instance, engaging suppliers from regions with advanced technologies can lead to the adoption of cutting-edge practices, which is crucial for staying competitive in 2025.

Tip: When searching for suppliers, consider utilizing digital platforms that specialize in connecting businesses with vetted manufacturers globally. This can streamline the selection process and ensure you are collaborating with reputable organizations.

Additionally, the 2023 Deloitte Manufacturing Industry Outlook highlights that companies prioritizing sustainable sourcing will enhance their brand reputation and appeal to environmentally conscious consumers. By embracing sustainability and ethical production methods, businesses can foster long-lasting relationships with suppliers who share similar values, creating a win-win scenario.

Tip: Always conduct thorough due diligence when vetting potential suppliers. Reviewing their certifications, customer feedback, and production capabilities can save you from future disruptions.

Innovative Tools and Resources for Supplier Management in 2025

In 2025, the landscape of supplier management will be revolutionized by innovative tools and strategic practices that align with sustainability and digital transformation. According to the 2025 Manufacturing Industry Outlook, manufacturers are making targeted investments in their digital frameworks, which are essential for fostering innovation amidst the ongoing skills gap. By embracing advanced technologies, businesses can optimize supplier relationships and streamline operations, ensuring better efficiency and responsiveness in the supply chain.

Additionally, as global firms harness artificial intelligence to mitigate supply chain disruptions, the integration of AI-driven tools is becoming increasingly vital. A recent study revealed that companies implementing AI solutions have managed to enhance operational resilience significantly. This data reflects a broader trend in which sustainable supply chain management not only improves performance but also responds effectively to stakeholder pressures. As such, firms that prioritize diversity in their supplier base and actively integrate sustainable practices will be better positioned to thrive in a competitive market. The utilization of these innovative resources will certainly unlock new potentials for supplier management in the upcoming years.