How to Choose the Best Car Engine Stand for Your Needs?

Choosing the right car engine stand is essential for both professionals and DIY enthusiasts. According to a recent industry report from Market Research Future, the automotive repair tools market is projected to grow at a rate of 5.3% annually. Among these tools, the car engine stand plays a critical role in ensuring safety and efficiency during engine repairs.

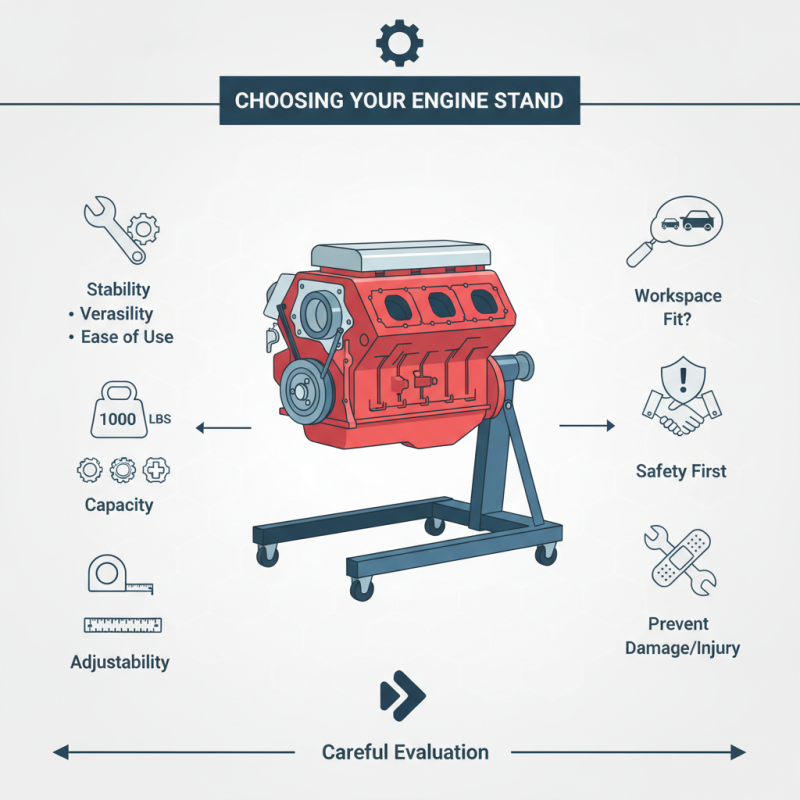

A reliable car engine stand should offer stability, versatility, and ease of use. Many stands can support up to 1,000 pounds, accommodating various engine sizes. However, not all stands are created equal, and users often face challenges in selecting the ideal model. Some may overlook essential factors like adjustability, weight capacity, and user-friendly designs.

As you navigate through your options, consider the specific needs of your projects. Will the stand fit in your workspace? Is it stable enough for your engine type? Reflecting on these questions can help prevent costly mistakes. A poorly chosen car engine stand can lead to injuries or damage, so careful evaluation is vital.

Understanding the Role of Car Engine Stands in Automotive Maintenance

Car engine stands play a crucial role in automotive maintenance. They provide stability while removing or installing an engine. A sturdy engine stand allows mechanics to work safely and efficiently. Without the right support, accidents can happen. Engine stands help to prevent costly damages and injuries.

When choosing an engine stand, consider its weight capacity. Not every stand can handle large engines. Verify the specifications carefully. Lightweight stands can be tempting but may not be safe. Safety should always be a priority.

Tips: Check the height and adjustability of the stand. A versatile stand allows for easier access to different parts. Aim for a design that offers mobility. This makes your workspace more convenient. Remember, a good engine stand should not only support the engine but also the mechanic's workflow.

How to Choose the Best Car Engine Stand for Your Needs? - Understanding the Role of Car Engine Stands in Automotive Maintenance

| Feature | Description | Weight Capacity | Material | Adjustability |

|---|---|---|---|---|

| Portability | Easily transportable for use in multiple locations | 1000 lbs | Steel | Height adjustable |

| Stability | Provides a stable base while working | 1200 lbs | Aluminum | Fixed height |

| Ease of Use | User-friendly design for easy engine mounting | 800 lbs | Steel | Rotatable |

| Cost Effectiveness | Value for money based on features | 900 lbs | High-strength polycarbonate | None |

Key Features to Look for in a Quality Engine Stand

When choosing a car engine stand, several key features matter greatly. Stability is crucial. A good stand should have a wide base. This prevents tipping during work. Look for thick, durable steel construction. It should easily hold the weight of your engine. Adjustable arms are another essential feature. They help secure different engine sizes. Without them, you might face alignment issues.

Portability is also important. If moving the stand is a hassle, you may not use it as often. Look for rubber casters or wheels that lock. This adds convenience, especially in tight spaces. The height adjustment feature is often overlooked. Having the ability to reposition the engine can make tasks much easier.

Consider how easy it is to assemble. Poor instructions can lead to frustration. You might find that certain stands are difficult to work with. It’s essential to read reviews before purchasing. In the end, the perfect stand should meet all your needs without breaking the bank. Evaluate your workspace and personal preferences carefully.

Comparison of Key Features in Car Engine Stands

Assessing Weight Capacity: Ensuring Your Stand Can Handle Engine Size

When selecting a car engine stand, weight capacity is crucial. Not every stand can handle all engines. A light stand might bend under a heavy load, causing issues. Look for stands that specify their weight limits clearly. Consider the weight of your engine before purchasing. An engine brings a lot of weight, especially a V8.

Tips for assessing weight capacity: Always check the manufacturer’s specifications. If a stand claims to hold 1,000 pounds, make sure that's accurate. Compare that number with the engine you have. If you are unsure, consult with professionals or experienced individuals.

Another factor to consider is stability. A stand that tips easily is of no use. Look for features like wider bases or extra bracing. Ensure the stand won't wobble, as this can lead to danger. Don’t overlook the quality of materials used; flimsy construction can lead to disaster.

Material Considerations: Steel vs. Aluminum Engine Stands

When choosing an engine stand, the material matters significantly. Steel and aluminum are the primary options available. Steel is known for its strength. It can handle heavy engines, making it a go-to choice for many professionals. Studies show that steel stands can support weights up to 1,500 pounds. However, they are often bulkier and may rust if not properly maintained.

On the other hand, aluminum offers some appealing benefits. It's lighter, making it easier to move around the workshop. For those managing smaller engines, an aluminum stand is often sufficient. Reports indicate that aluminum stands typically support engines weighing around 1,000 pounds. However, the lighter weight does come with a trade-off. While they resist corrosion better, aluminum stands may dent or bend when handling heavier loads.

Both materials have drawbacks. Steel stands can be cumbersome and less portable. Aluminum, while easier to maneuver, may not provide the same durability in extreme conditions. It's essential to reflect on specific needs before making a choice. Are you figuring out which engine combinations you’ll work with most often? Knowing these details can guide a better decision.

Safety Standards and Stability Factors for Engine Stands

When selecting an engine stand, safety standards should be a priority. The construction material matters greatly. Opt for sturdy steel frames that can withstand heavy loads. Check the weight capacity before purchasing. Occasionally, these stands may be rated lower than expected, leading to risk. Always verify that the stand meets industry safety guidelines.

Stability is key when working on engines. A well-designed engine stand should have a wide base. This helps prevent tipping during use. Some models feature adjustable arms, but they can wobble if not secured properly. Inspect the locking mechanisms regularly. Weak points can compromise safety.

Consider the overall design as well. Engine stands with wheels can enhance mobility, but they may not be as stable. Lockable wheels are essential. A stand that rolls away can create dangerous situations. Reflect on your workspace and engine size. Not all stands fit well in cramped areas. A poor fit can lead to accidents. Finding the right balance between mobility and stability is crucial.